Tin tức

Aluminum Extrusion Dies – The Core Element Behind High-Quality Aluminum Profiles

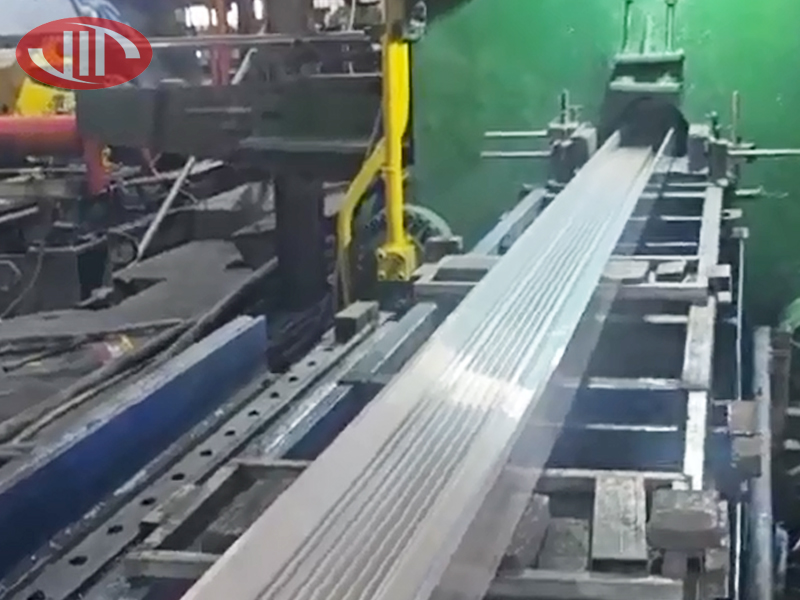

In the manufacturing process of aluminum profiles, the extrusion die is considered the "heart" of extrusion technology. The die directly determines the shape, durability, precision, and surface quality of the final aluminum product.

At Viet Y Aluminium Factory, extrusion dies are not merely production tools—they are the result of a comprehensive process of research, design, machining, and strict quality control. This showcases the high technical expertise and quality commitment that Viet Y Aluminium delivers to its customers.

What is an Aluminum Extrusion Die?

An aluminum extrusion die is a metal tool with one or more profile die openings, used to shape aluminum billets when they are forced through the die under high pressure. This process is known as aluminum extrusion. Depending on the die’s design, the resulting profiles can vary in shape—such as square tubes, U-channels, T-sections, grooved bars, rounded edges, and more—serving various industries including construction, interior design, mechanical engineering, electronics, and advertising.

Die Design and Manufacturing Process at Viet Y Aluminium

At Viet Y Aluminium Factory (Nguyen Khe Industrial Zone – Dong Anh – Hanoi), the entire die system is developed following a structured and professional process:

1. Receiving Technical Requirements and Drawings

Customers provide technical drawings or specifications, and our team of experienced engineers consults and proposes the optimal die design to ensure both performance and profile accuracy.

2. Die Design Using CAD/CAM Software

Advanced software such as AutoCAD, SolidWorks, and Moldflow is used to simulate the die structure, material flow, and evaluate potential challenges before actual production begins.

3. High-Precision CNC Machining

Die steel blocks are machined using multi-axis CNC machines to ensure exceptional precision. Afterward, the dies undergo heat treatment and are coated to resist wear and extend their lifespan.

4. Assembly and Trial Testing

After machining, dies are assembled and tested by extruding sample profiles. These are checked for consistency, dimensional accuracy, and surface finish. Only dies that meet all standards proceed to mass production.

Advantages of Extrusion Dies at Viet Y Aluminium

- High Precision: Every component is processed with CNC technology, ensuring minimal tolerance and consistent profile dimensions.

- Superior Durability: Made from specialized alloy steel, the dies withstand high temperatures and resist wear, offering long-term reliability.

- Versatile Designs: Viet Y Aluminium can custom-design and produce hundreds of die models—from standard architectural systems to complex technical structures.

- Production Efficiency: Smartly engineered dies reduce extrusion cycle times, minimize technical issues, and boost overall productivity.

Why Are Extrusion Dies So Important?

A high-quality extrusion die ensures that:

- Aluminum profiles have sharp, well-defined edges

- Wall thickness is uniform and stable

- Minimal post-extrusion corrections are needed

- Production efficiency increases while maintenance costs decrease

That’s why Viet Y Aluminium continually invests in die design and manufacturing—not only to serve its internal production needs but also to meet custom orders and specialized project requirements.

Contact Information of Viet Y Aluminium Co., Ltd

Address: Nguyen Khe Industrial Cluster, Dong Anh District, Hanoi, Vietnam

Hotline: 0904.217.729 | Zalo/Wechat: 0968.217.729 | Email: vietyaluminiumjcs@gmail.com

Bài viết mới nhất

Viet Y Aluminium Comprehensive Custom Aluminum Fabrication Solutions, International Standard Quality

Viet Y Aluminium Offers Wood Grain Film Coating Services Diverse Colors, Beautiful Finish, International Standard Quality

Viet Y Aluminium A Trusted Aluminium Processing Partner and One of the Leading Manufacturers in Vietnam

Viet Y Aluminium Provides One Stop Laser Cutting & Welding Services Tailored to Customer Requirements International Standard Quality