Tin tức

Processing and Manufacturing of Permanent Aluminum Connectors at Viet Y Aluminum Factory

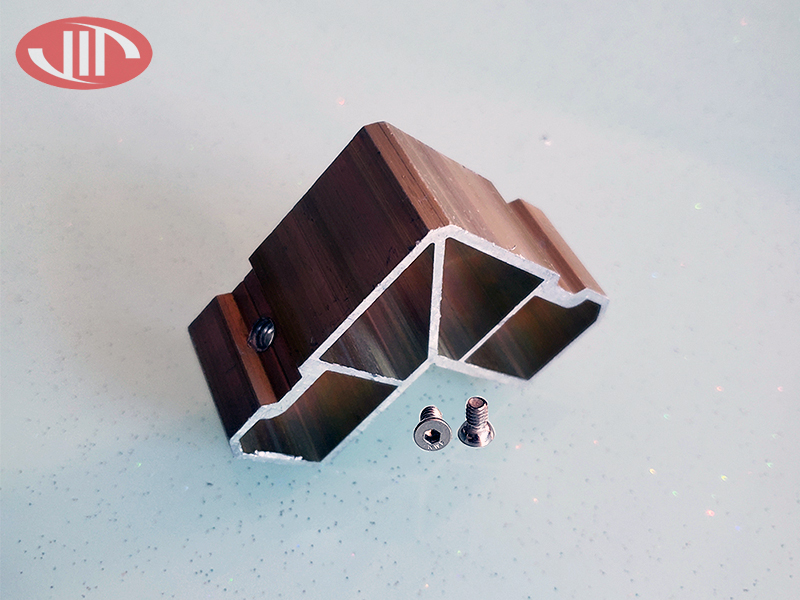

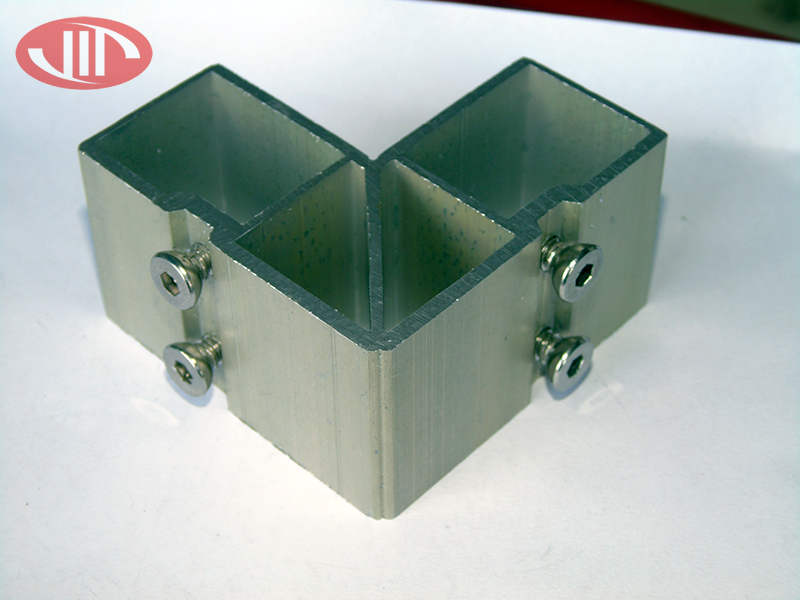

In modern aluminum door systems, permanent connectors (also known as aluminum corner brackets or structural connectors) are essential components. They play a pivotal role in corner jointing, ensuring the overall strength, aesthetics, and durability of the door structure.

At Viet Y Aluminum Factory, the processing and manufacturing of permanent connectors follow a well-invested procedure, applying advanced technology to deliver high-quality, uniform, and long-lasting products.

What is a Permanent Connector?

A permanent connector is an embedded component used to connect extruded aluminum profiles, typically at 90-degree angles in doors, windows, and aluminum-glass partitions. It is referred to as "permanent" due to its specialized design, which enhances load-bearing capacity, resists twisting and warping, and eliminates the need for welding, thereby improving the durability of the final aluminum product.

Production Process of Permanent Connectors at Viet Y Aluminum

1. Design and Material Selection

Depending on the aluminum system used, Viet Y Aluminum designs connectors that meet technical standards or specific customer requirements. The main materials used are pure aluminum or high-quality aluminum alloys with excellent strength and corrosion resistance.

2. Extrusion of Connector Billets

Aluminum billets are heated and extruded through specialized molds to form connector profiles. This stage uses modern hydraulic extrusion machines to ensure precision and uniformity.

3. Cutting and Mechanical Processing

After extrusion, the connector profiles are cut to standard sizes or according to technical drawings. Viet Y Aluminum uses CNC cutting systems along with milling, drilling, and punching machines to create features such as sliding grooves, screw holes, and joint ends—ensuring perfect alignment with aluminum door profiles.

4. Surface Treatment and Finishing

Post-processing, the permanent connectors undergo surface treatments such as powder coating, anodizing, or anti-corrosion plating depending on application requirements. The surfaces are smoothed and evenly coated, enhancing adhesion and aesthetics during installation.

5. Quality Inspection and Packaging

Before delivery, each permanent connector is inspected for dimensions, hardness, load capacity, and compatibility with the aluminum system. Products that meet the standards are carefully packaged with clearly labeled specifications.

Key Advantages of Viet Y Aluminum Permanent Connectors

- High precision, 100% compatibility with aluminum profile systems

- Durable quality, rust-free, deformation-resistant over time

- Flexible design, available for custom manufacturing

- High-volume production, fast lead times, and competitive pricing

For more information or custom orders, please contact Viet Y Aluminum – where “Trust begins with quality.”

Contact Information of Viet Y Aluminium Co., Ltd

Address: Nguyen Khe Industrial Cluster, Dong Anh District, Hanoi, Vietnam

Hotline: 0904.217.729 | Zalo/Wechat: 0968.217.729 | Email: vietyaluminiumjcs@gmail.com

Bài viết mới nhất

Viet Y Aluminium Comprehensive Custom Aluminum Fabrication Solutions, International Standard Quality

Viet Y Aluminium Offers Wood Grain Film Coating Services Diverse Colors, Beautiful Finish, International Standard Quality

Viet Y Aluminium A Trusted Aluminium Processing Partner and One of the Leading Manufacturers in Vietnam

Viet Y Aluminium Provides One Stop Laser Cutting & Welding Services Tailored to Customer Requirements International Standard Quality