Tin tức

Standardized Production Process of Technical Corner Brackets at Viet Y Aluminium Factory

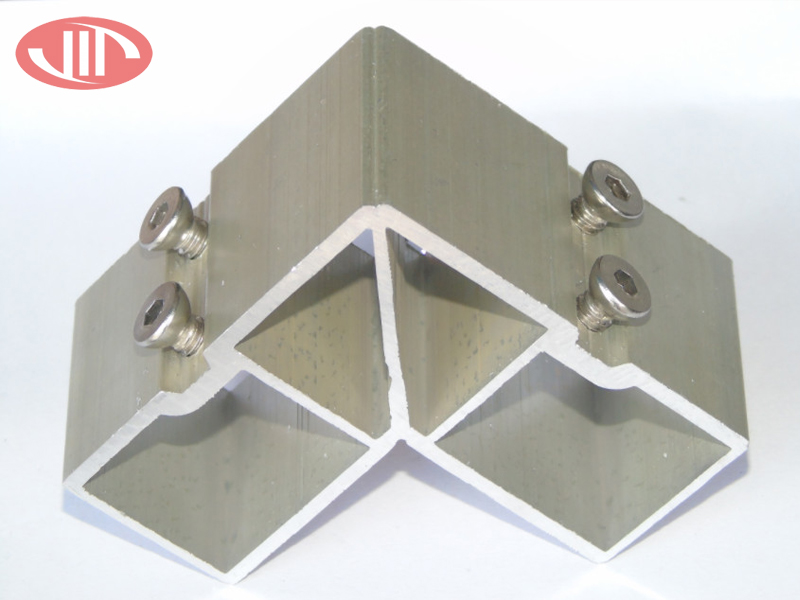

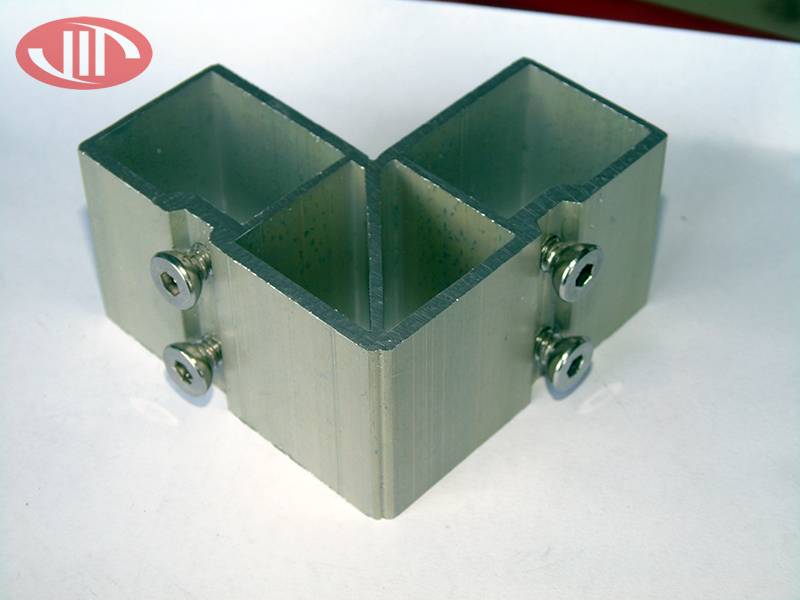

In the modern aluminium door manufacturing and installation industry, corner brackets (ke vĩnh cửu) are indispensable components. These brackets serve as the primary load-bearing elements at joint corners, ensuring high durability, precise right angles, and long-term smooth operation of the door system. At Viet Y Aluminium Factory, the production of corner brackets follows a strictly controlled process—from design to machining—to deliver products that meet technical standards and perfectly fit aluminium profile systems.

1. Technical Design – The Foundation of Quality

The process begins with receiving door system drawings or actual samples from the client. Viet Y Aluminium’s experienced engineering team analyzes the aluminium structure, corner load distribution, and develops the most suitable corner bracket design.

All designs are created using specialized CAD/CAM software to accurately simulate the bracket’s shape, drilling positions, guiding grooves, and structural integrity. Load simulation ensures the final product resists warping or deformation during installation and use.

2. Selection of High-Quality Materials

Viet Y Aluminium’s corner brackets are made from 6063-T5 or 6005 standard aluminium alloys, known for excellent strength, machinability, and corrosion resistance. All input materials undergo strict testing for chemical composition and physical properties using advanced analytical equipment to ensure consistent quality across the entire batch.

3. Extrusion – Forming the Base Shape

Aluminium billets are heated to 480–500°C and then extruded through a hydraulic press to form the initial bracket shape. Each product line uses a custom-designed mold, ensuring sharp details and uniform geometry in the extruded bracket profiles.

4. CNC Precision Machining

This is a critical step that defines the technical accuracy of the final product. After extrusion, the bracket profiles are transferred to multi-axis CNC machines for detailed processing, including:

- Cutting to standard dimensions

- Drilling precise screw holes

- Milling connection grooves and anti-rotation ridges

- Creating drainage or concealed bracket slots

Every step is automated and monitored with digital sensors, ensuring a dimensional tolerance within ±0.1 mm.

5. Surface Treatment for Durability and Aesthetics

Depending on customer requirements, corner brackets can be surface-treated using modern technologies:

- Anodizing: Forms a protective oxide layer for enhanced corrosion resistance

- Powder Coating: Matches the door color for improved aesthetics

- Chrome Plating or Mechanical Polishing: Increases surface hardness and product lifespan

6. Inspection – Packaging – Delivery

Before shipment, every batch of corner brackets undergoes strict quality control, including:

- Dimensional measurement and flatness inspection

- Load-bearing strength testing at bracket corners

- Model comparison with design drawings

Approved products are batch-packaged, labeled with traceable QR codes, and delivered to the customer.

Contact Information of Viet Y Aluminium Co., Ltd

Address: Nguyen Khe Industrial Cluster, Dong Anh District, Hanoi, Vietnam

Hotline: 0904.217.729 | Zalo/Wechat: 0968.217.729 | Email: vietyaluminiumjcs@gmail.com

Bài viết mới nhất

Viet Y Aluminium Comprehensive Custom Aluminum Fabrication Solutions, International Standard Quality

Viet Y Aluminium Offers Wood Grain Film Coating Services Diverse Colors, Beautiful Finish, International Standard Quality

Viet Y Aluminium A Trusted Aluminium Processing Partner and One of the Leading Manufacturers in Vietnam

Viet Y Aluminium Provides One Stop Laser Cutting & Welding Services Tailored to Customer Requirements International Standard Quality